귀사의 업무 협조에 감사 드리며 무궁한 발전을 기원합니다.

표제의 건 관련, 부품공급 가능 기간 아래와 같이 안내 드리오니 업무에 참조 바랍니다.

기본적으로 단종 후 8년간 부품 공급 가능 및 이후 2년간 제한적인 부품 공급 및 AS 가능

단종 시점에서 연차 경과에 따라서 납기가 길어지고, 상황에 따라서 공급이 불가능한 경우도 발생할 수 있음.

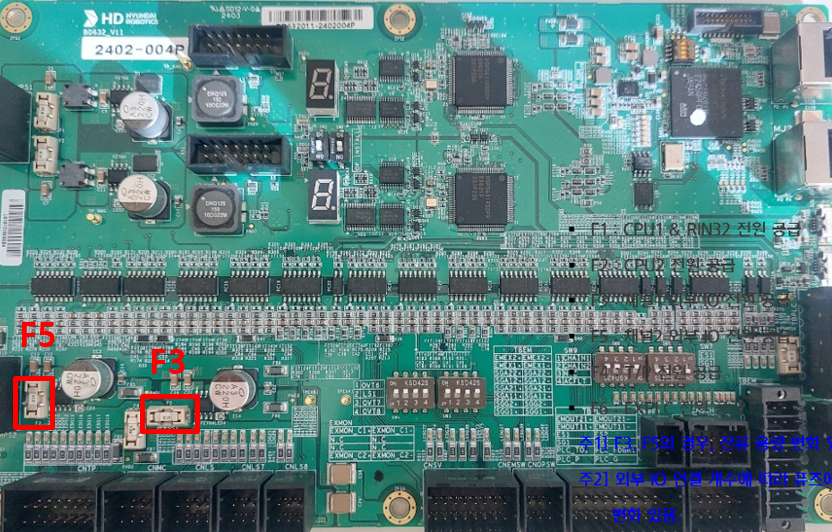

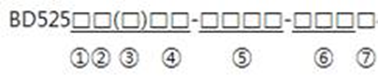

1. 제어기

| 순 | 모델명 | 단종 | 주요부품 공급가능기한 |

|---|---|---|---|

| 1 | Hi4, Hi4a | 2010년 | 보유 재고에 한해 공급 가능, 별도 문의 |

| 2 | Hi5 | 2015년 | 2025년까지 |

| 3 | Hi5a-N | 2021년 | 2031년까지 |

| 4 | Hi5a-S | 2024년 | 2034년까지 |

주요부품: PCB류, 서보엠프, TP

2. 본체

| 순 | 모델명 | 단종 | 주요부품 공급가능기한 |

|---|---|---|---|

| 1 | HR, HX (Hi4, Hi4a) | 2010년 | 보유 재고에 한해 공급 가능, 별도 문의 |

| 2 | HX300, HX200L (Hi5) | 2015년 | 2025년까지 |

| 3 | HA006, HA020, HA010L, HA006A, HA020W, HA010LW | 2015년 | 2025년까지 |

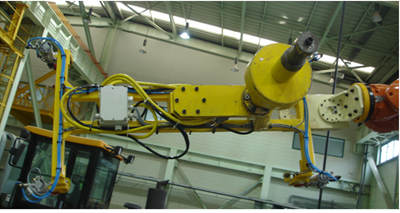

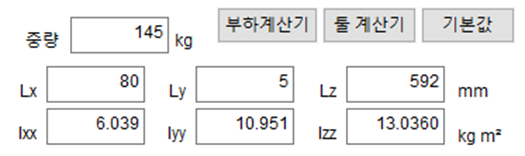

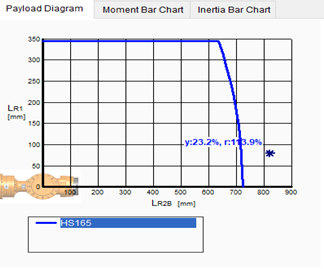

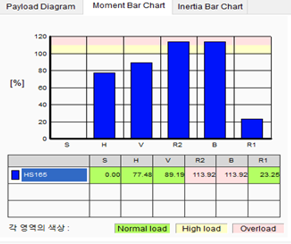

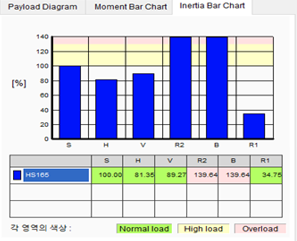

| 4 | HS165, HS165S, HS200, HS150L, HS165D | 2016년 | 2026년까지 |

| 5 | HS200S | 2019년 | 2029년까지 |

| 6 | HH130L, HH100SL, YS140, HA006E | 2022년 | 2032년까지 |

| 7 | HX400S | 2023년 | 2033년까지 |

| 8 | HS260, HX500 | 2024년 | 2034년까지 |

| 9 | HA006B, HH012A, HH020, HH010L, HA006L, HH020L | 2025년 | 2035년까지 |

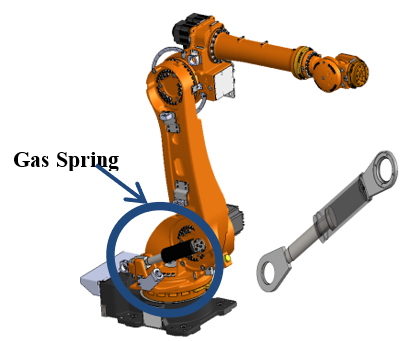

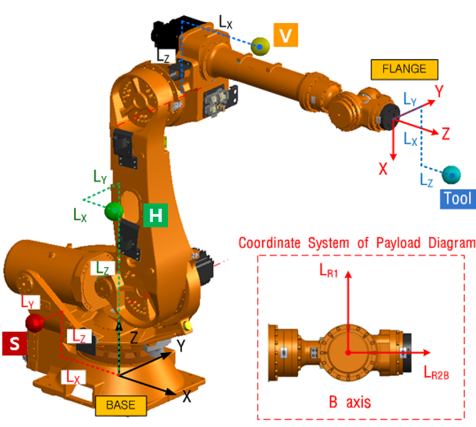

주요부품: 모터, 감속기, 외배케이블, WRIST ASSY, Balance Spring

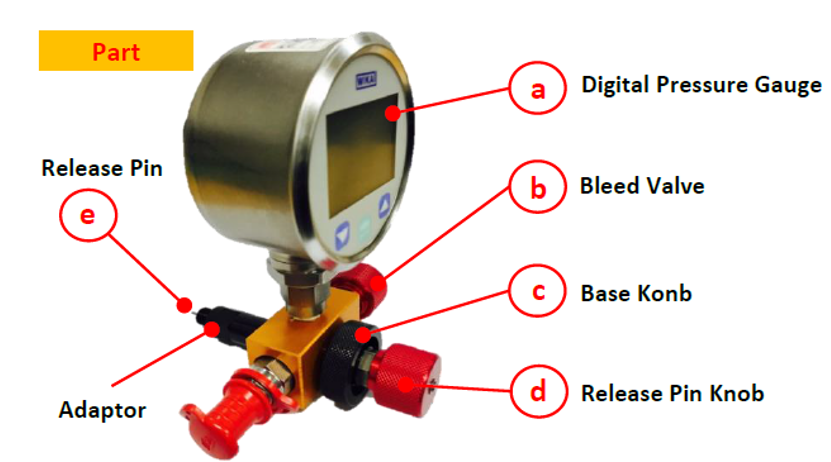

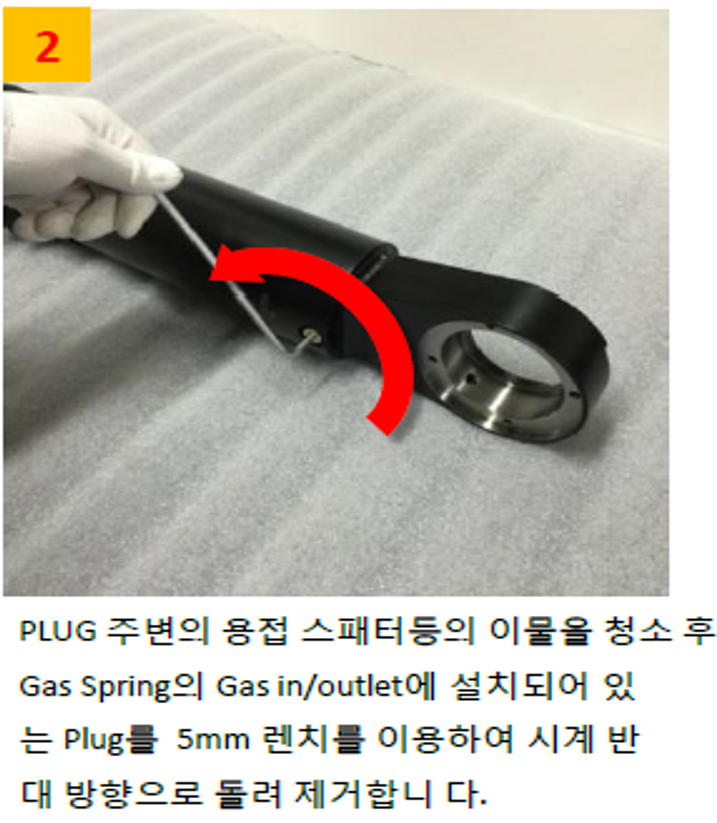

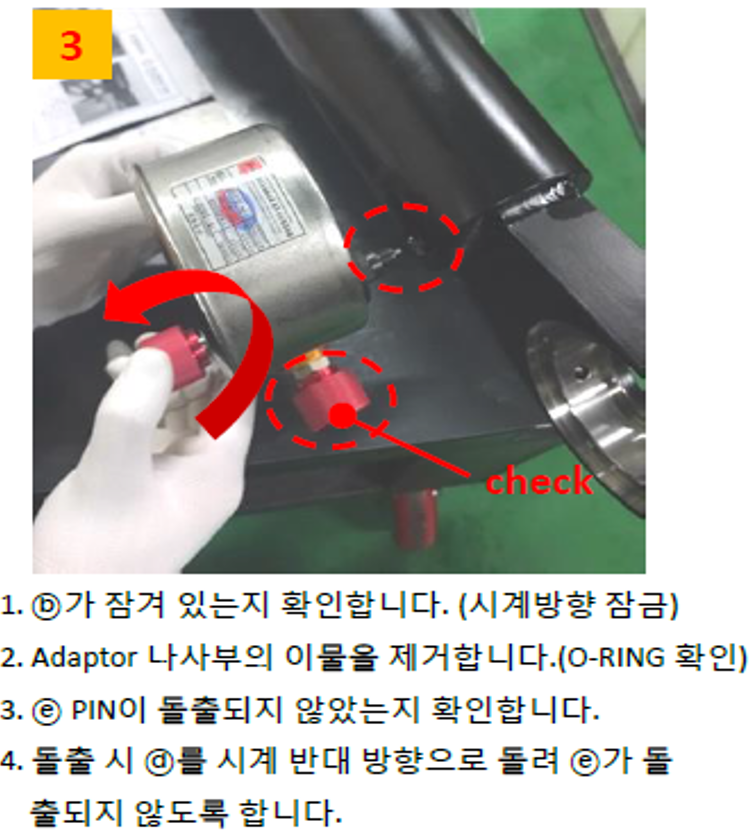

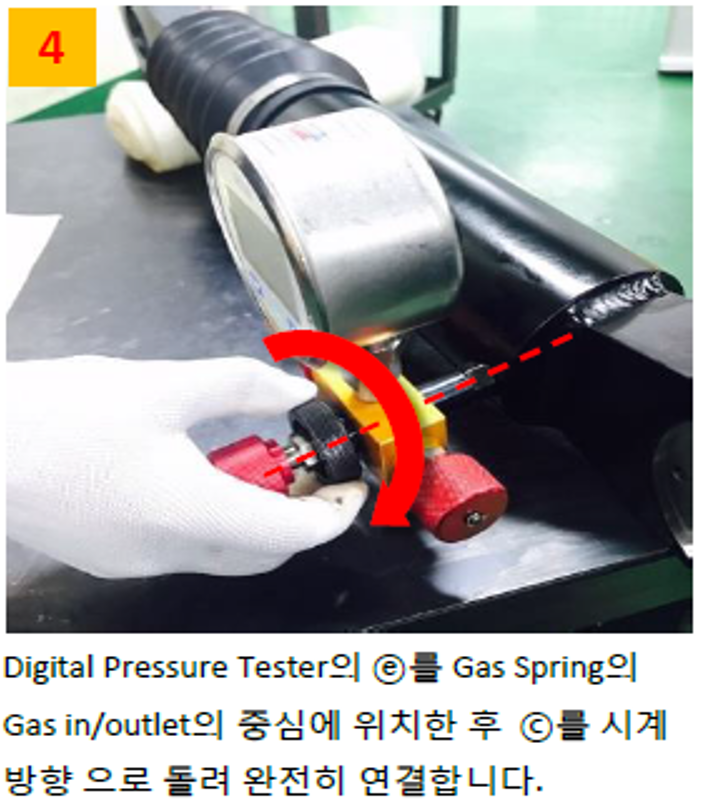

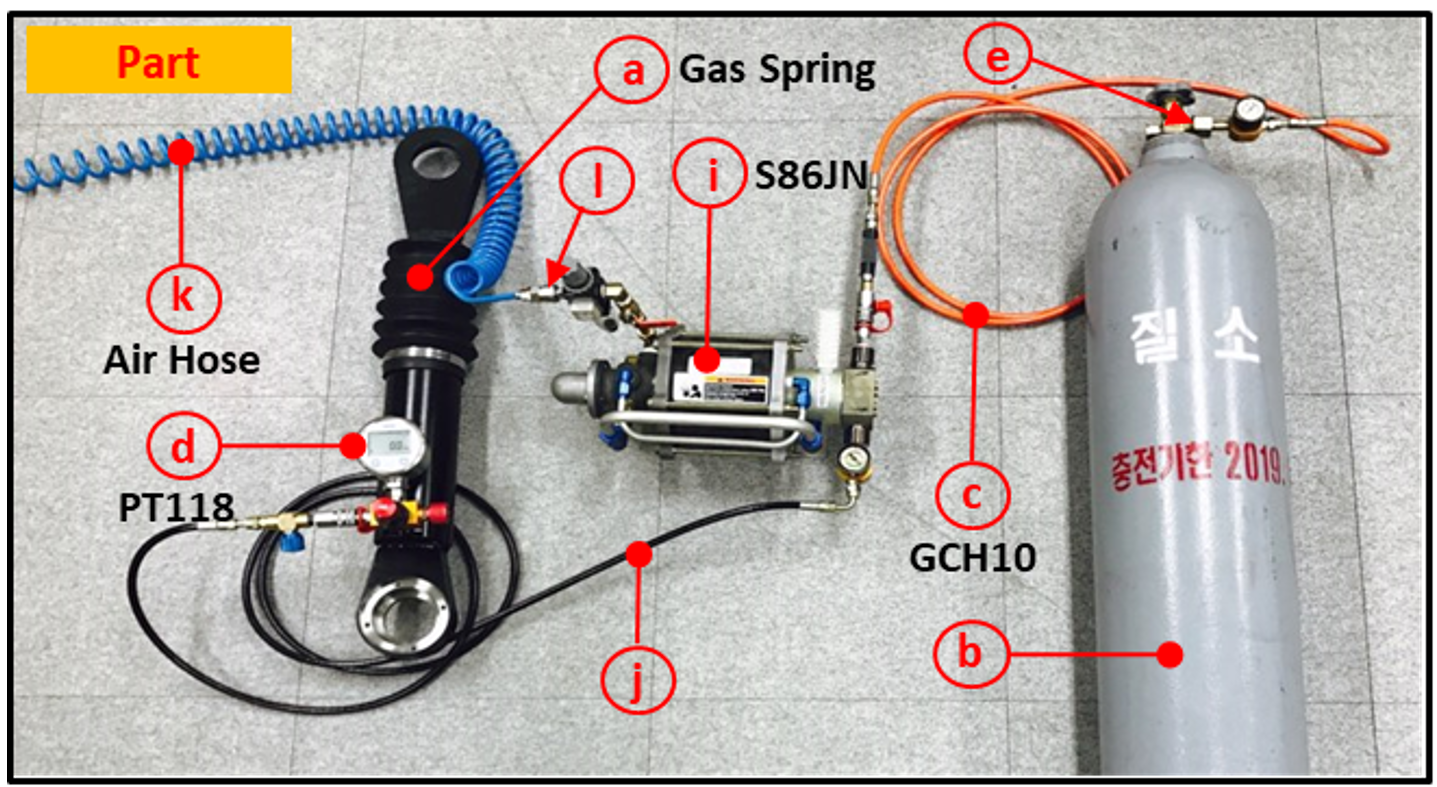

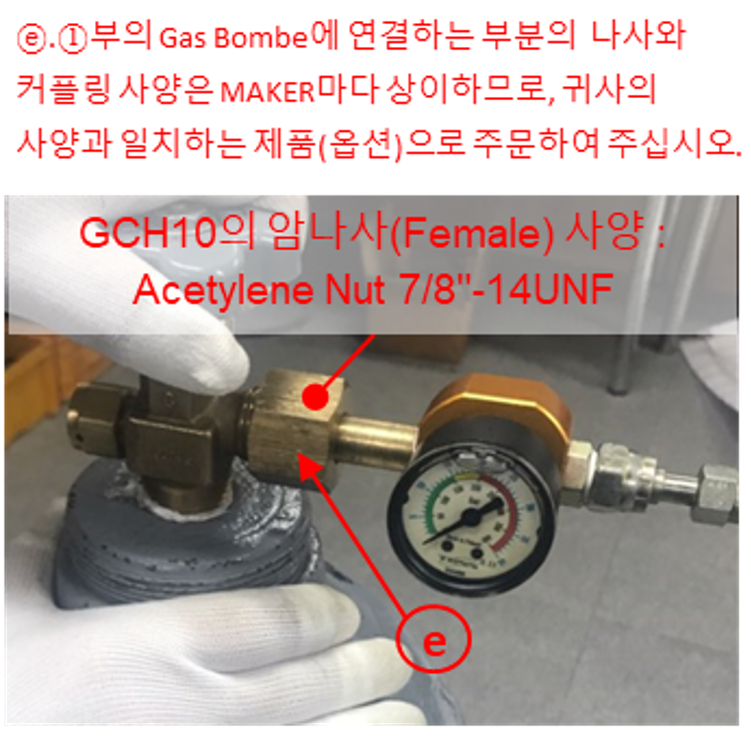

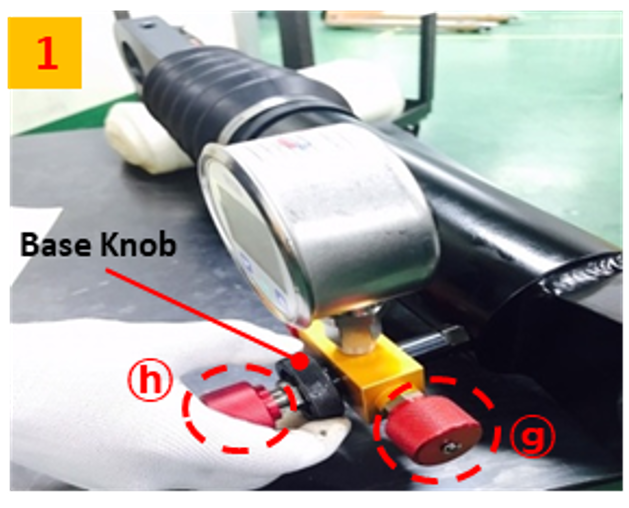

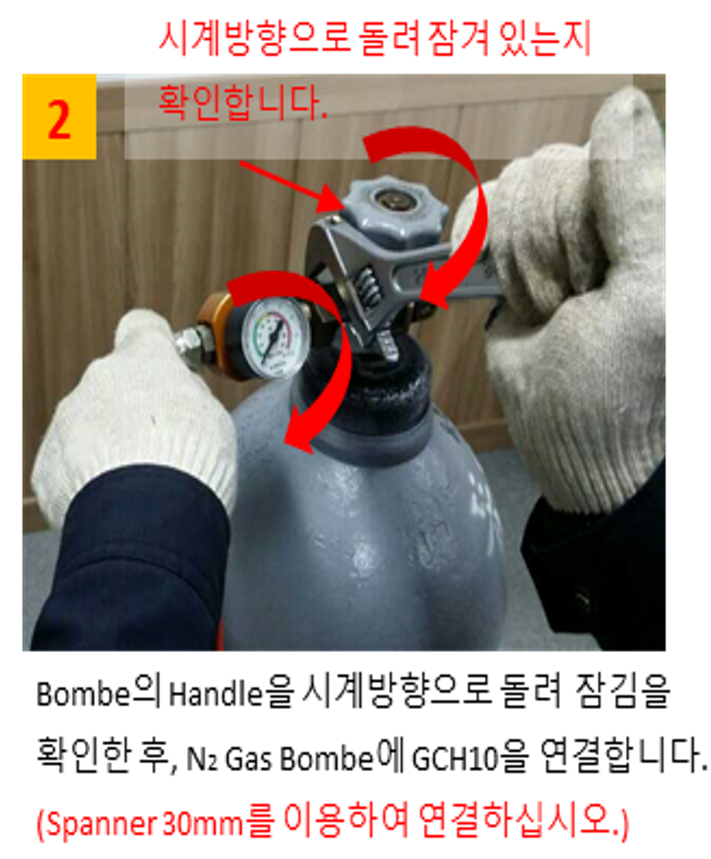

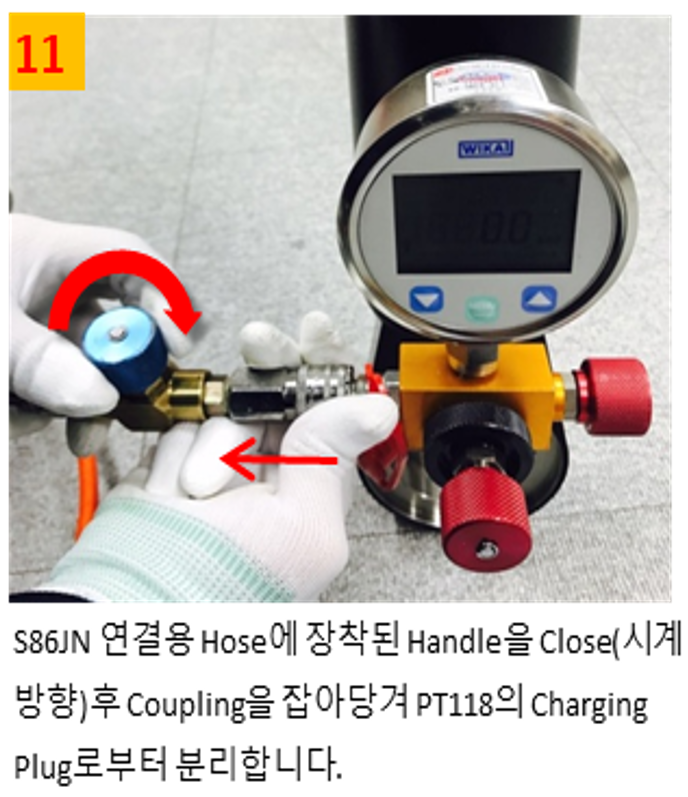

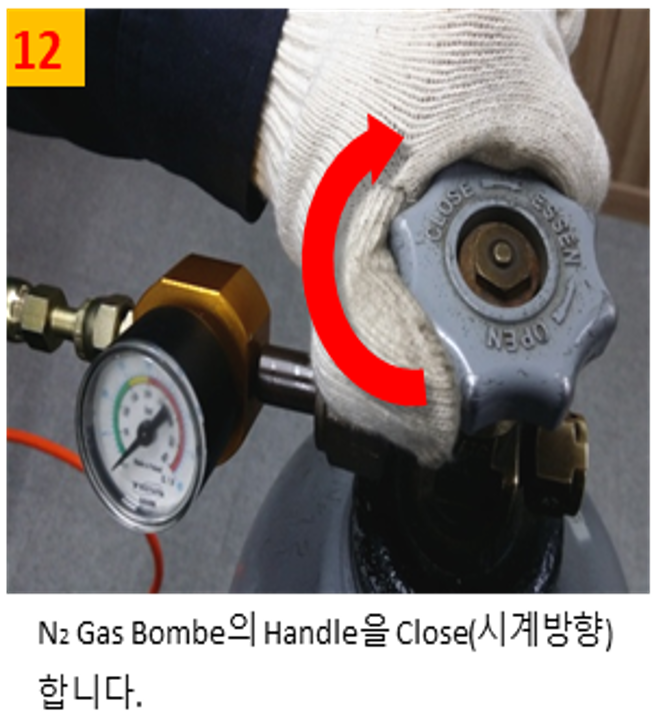

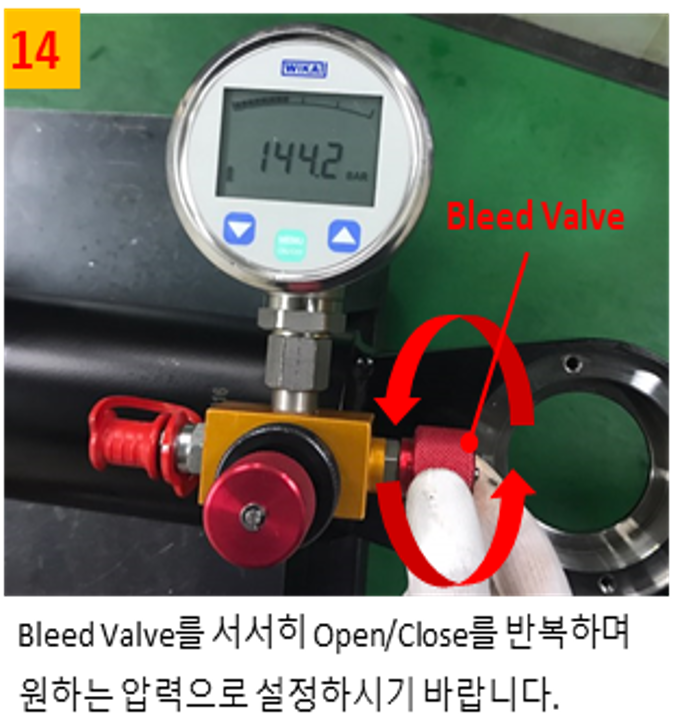

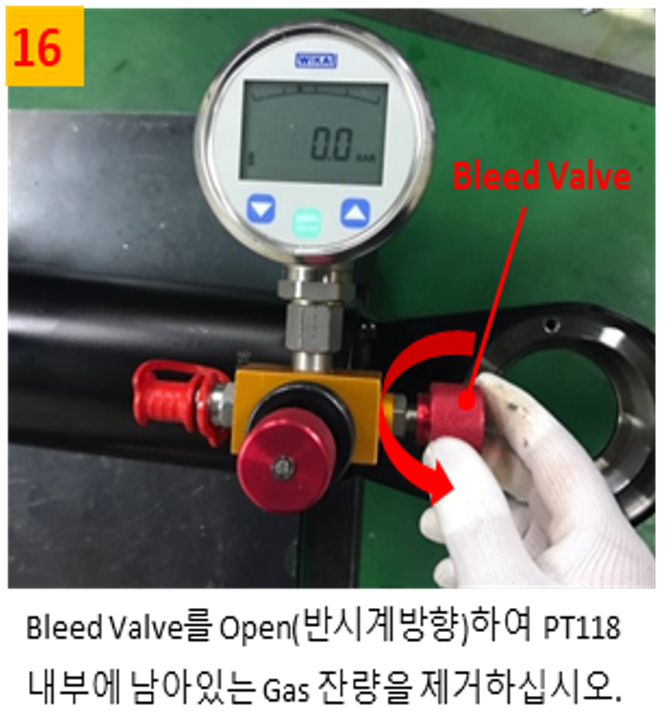

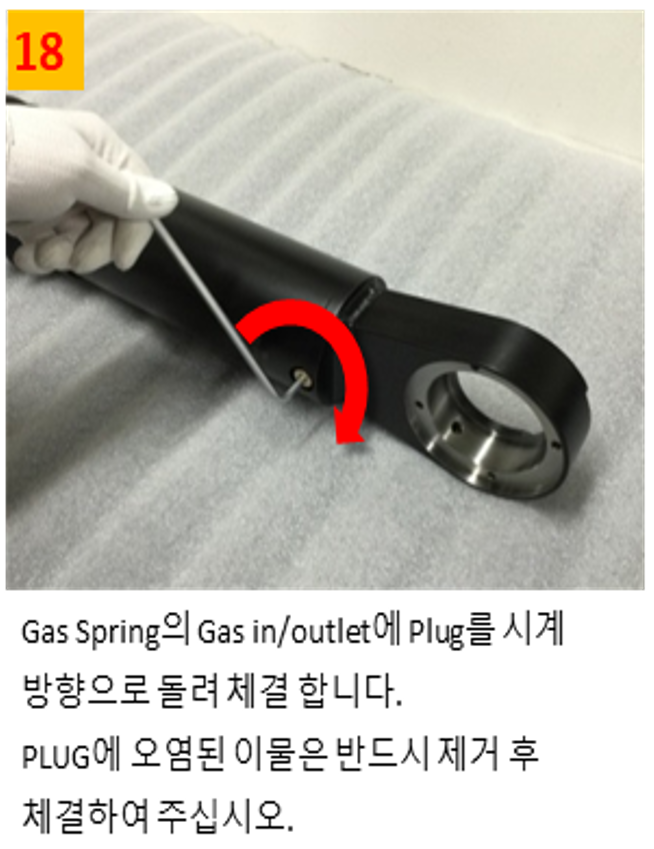

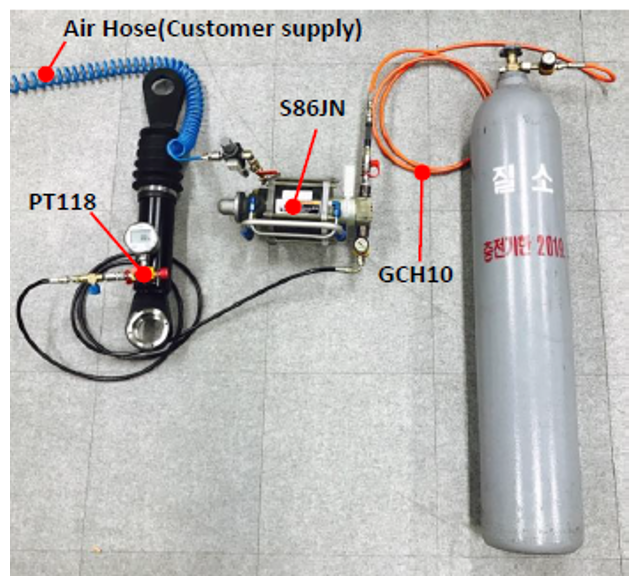

Gas spring filler SET

Gas spring filler SET

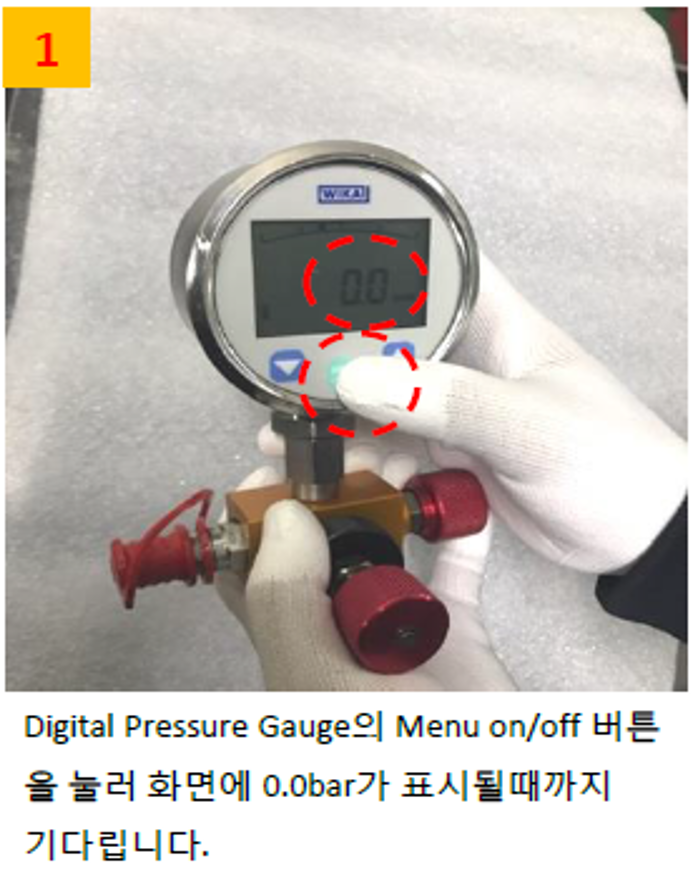

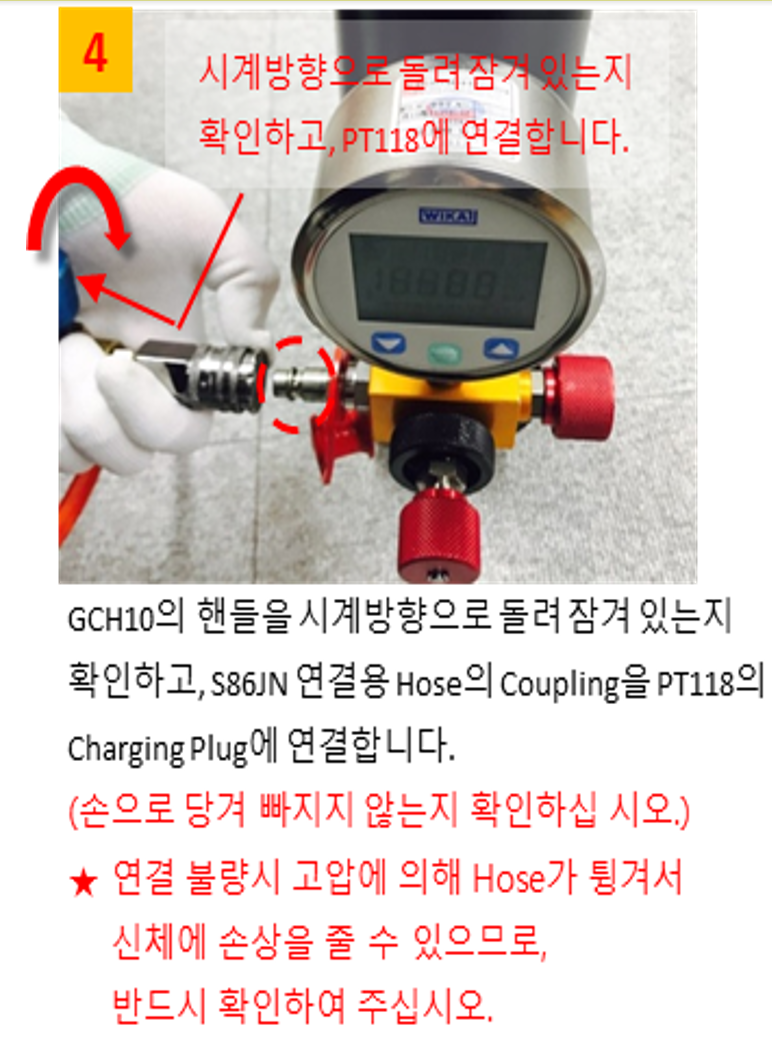

(digital pressure meter)

(digital pressure meter)

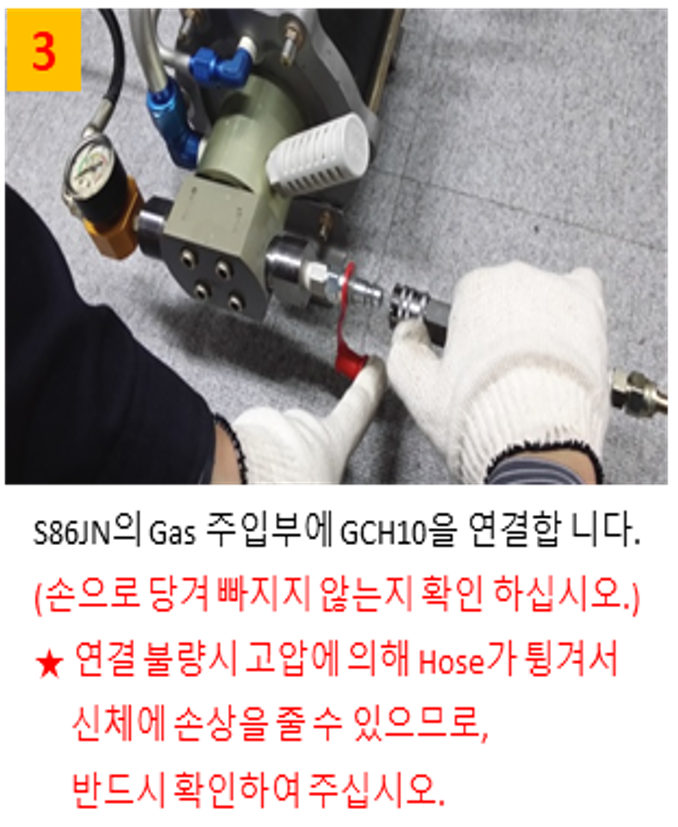

(pressure injection booster)

(pressure injection booster)