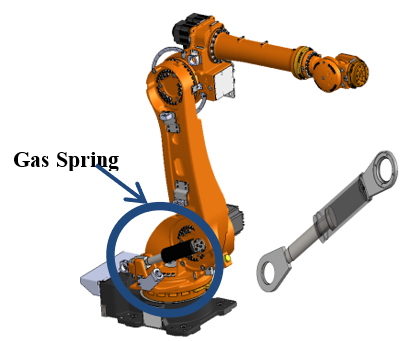

Gas springs have the advantage of being lighter and requiring less replacement time than coil springs, but as they are devices that use high-pressure gas, natural leaks occur. Periodic inspection by the user is required to manage this.

| Application Model | HS180/220, HH300,HS200L |

|---|---|

| Replacement M/H | 0.5 hours (depending on environment) |

| integrity | Periodic inspection. Twice a year (refer to manual) |

caution

- Problem that occurs when gas spring pressure drops: H-axis overload error occurs (robot stops)

- Depends on the level of leakage. Depending on the load on the H axis, it may not occur even if the entire amount of leakage occurs.

- Overcurrent warning occurs (H-axis warning needs to be checked)

How to check pressure

Apply pressure automatic detection function (Hi5a version MV40.17.00 or higher)

- Warning occurs below 60 bar

- Error occurs below 30 bar (robot stops)

- Warning level can be manually set in T/P (details announced later)

Manual measurement using a pressure gauge (general pressure gauge: digital (PT118) recommended)

How to respond when pressure drops

| pressure(bar) | Action take | meaning | note |

|---|---|---|---|

| 140~100 | maintain | There is no or minimal leakage. | |

| 100 or less | gas filling | Pressure decrease due to natural leakage | Use after filling |

| 100 or less | substitute | Rapid deterioration due to seal damage | First filling test required |

- Problems when using gas springs while neglecting natural pressure drop

- The friction angle between the cartridge and the tube increases, causing damage to the seal.

- Early damage to gas springs occurs