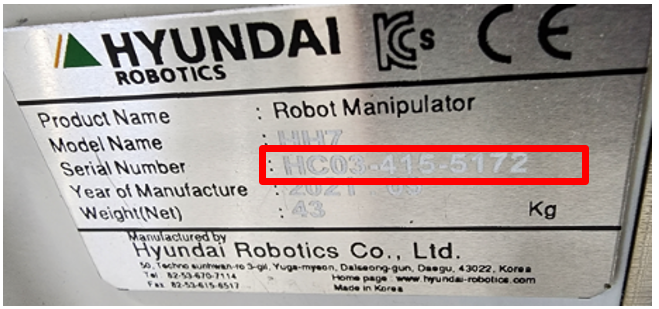

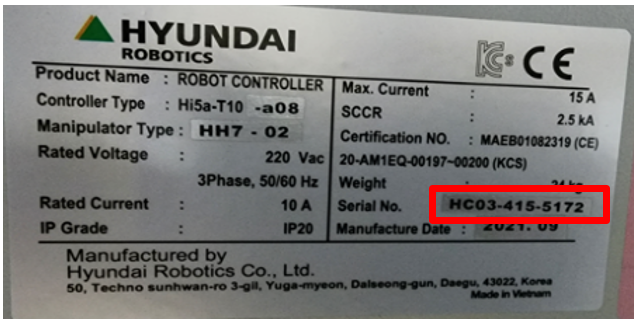

Check whether the robot body and the controller number are the sam

If there are multiple robots, be careful of mixing the main body and controller!

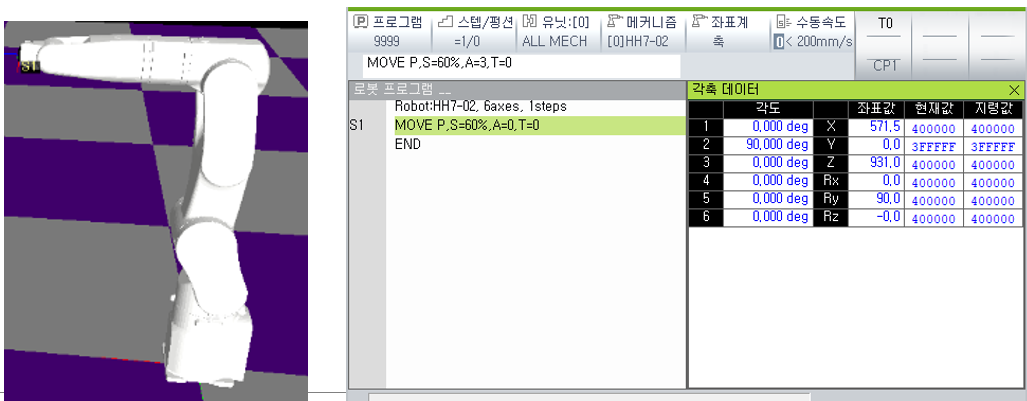

Select robot program (JOB file: No. 9999) and move

- Select program (press Shift key + Program-Step key simultaneously), enter 9999 and press ENTER

- Select step number (Press Program-Step key / 1 input ENTER)

- Robot operation: Motor ON - Deadman switch ON - Step forward (FDW) and move to step 1

- After moving, the data should be the left posture below and each axis data on the right.

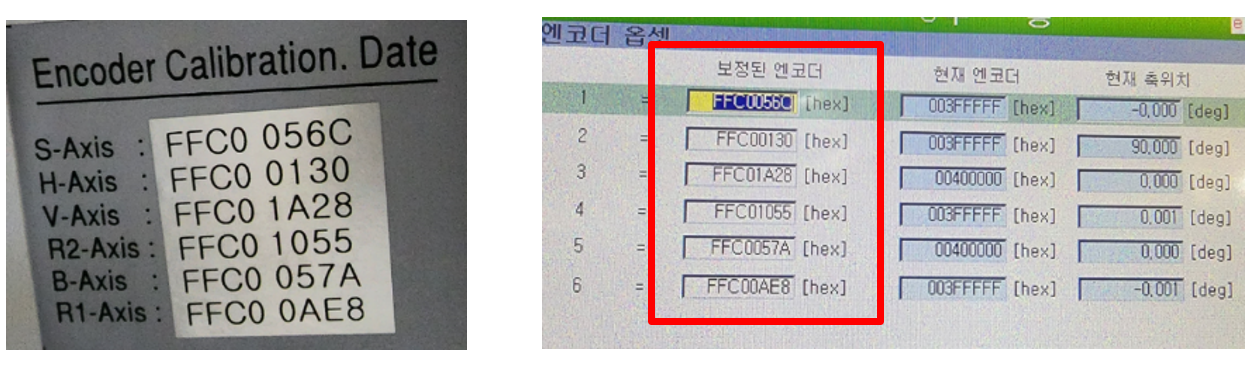

The encoder recorded value attached to the control panel and the left corrected encoder value of the TP encoder offset must be the same

(System – Robot Parameters – Encoder Options Screen)

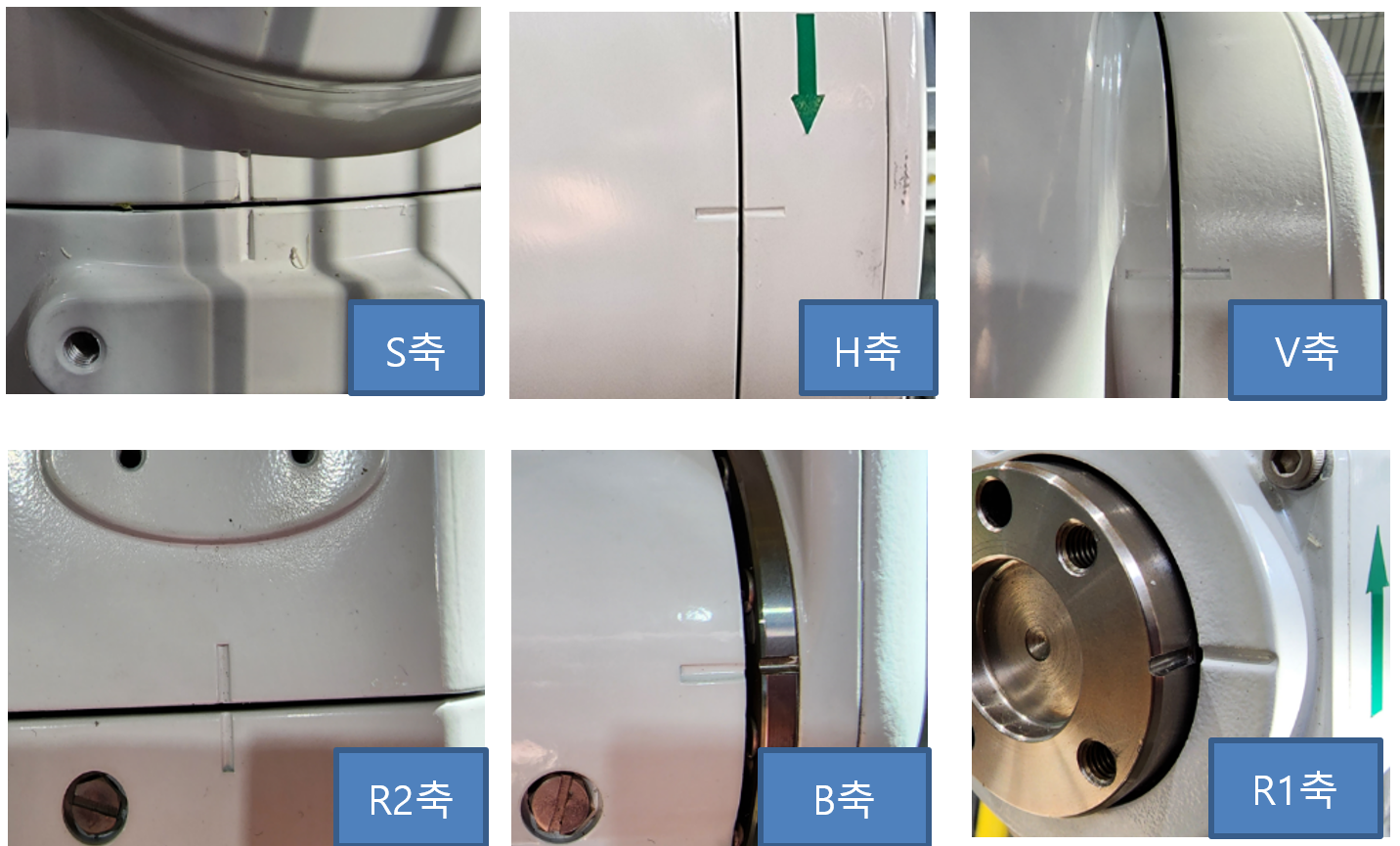

Check whether the scale of each axis of the robot body matches